IH Induction Cookers

from Induction Direct

Saving energy means keeping your money in your own pocket where it belongs

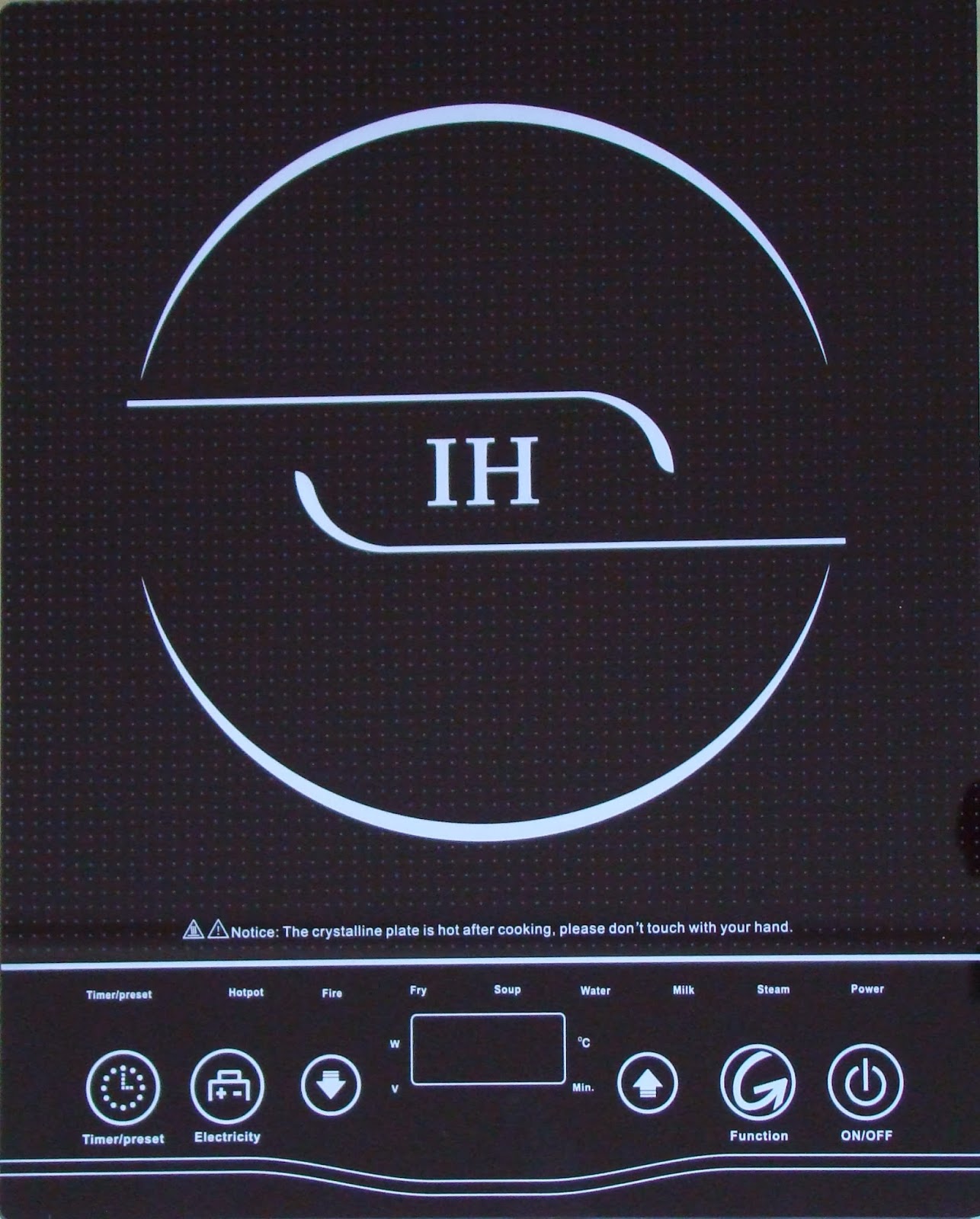

IH GTA 12 Induction Cooker with touch controls

How Induction Cookers

Operate

An induction cooker uses

induction heating for cooking. Unlike other forms of cooking, heat is generated

directly in the pot or pan (cooking vessel), as opposed to being generated in

the stove top by electrical coils or burning gas.

To be used on an induction

cooker, a cooking vessel must be made of a ferrous metal.

In an induction cooker, a

coil of copper wire is placed underneath the cooking pot made of a material

which must be electrically conductive and ferromagnetic.

An alternating electric current flows through the coil, which produces an

oscillating magnetic field. This field induces an electric current in the pot.

Current flowing in the metal pot produces resistive heating which heats the

food. While the current is large, it is produced by a low voltage. Induced

current can heat any type of metal, but the magnetic properties of a steel

vessel concentrate the current in a thin layer near the surface, which makes

the heating effect stronger. Practical induction cookers are designed for

ferromagnetic pots; users are advised to use only pots on which a magnet will

stick. Non-ferrous metals have a skin depth that is too thick, lowering the

resistance seen by the induced current and so making these metals unusable on

an induction cooker. Since heat is being generated by an induced electric

current, the unit can detect whether cookware is present (or whether its

contents have boiled dry) by monitoring how much power is being absorbed that

allows such functions as keeping a pot at minimal boil or automatically turning

an element off when the pot runs out water or the cookware is removed from

it.

The pancake pancake inductor coil used in our IH GTA 12 and GTB 2 Induction Cookers

A strong magnetic field is

produced by the pancake inductor coil which is clearly seen in this photograph

above, ferrite rods beneath the copper coil repel the magnetic field,

concentrating the field onto the cookware above.

This process pushes the electrons in the cookware above in and out of alignment, generating heat through intermolecular friction.

The circuit board with CPU used in our IH GTA 12 and GTB 2 Induction Cookers

The Central Processing Unit

or computer on the circuit board above sends current to the Insulated Gate

Bipolar Transistor or IGBT which chops up the electric current’s wavelengths,

rapidly turning the power on and off, the electric current is then sent

to the pancake inductor coil, which produces a strong magnetic field. A Sensor

in the middle of the coil detects and maintains the temperature of the cookware

above.

IH GTB 2 Induction Cooker with press button controls

This form of cooking has

certain advantages over conventional gas flame and electric cookers, as it

provides rapid heating, improved thermal efficiency, and greater heat

consistency, greater safety yet with precise control similar to gas. In

situations in which a hot plate would typically be dangerous or illegal, an

induction plate is ideal, as it creates no heat itself.

The time to boil a certain

amount of water depends upon the amount of water but it is typically a few

minutes. Heating is much faster without water, e.g., for stir frying, a thin

pan containing three tablespoons of oil may heat up to stir fry temperature in

as little as ten seconds.

Induction cookers are safer

to use than conventional cookers because there are no open flames and the

element itself reaches only the temperature of the cooking vessel; only the pan

generates heat. Induction cookers are easy to clean because the cooking surface

is flat and smooth, even though it may have several heating zones.

The cooking surface is made

of a material which is a poor heat conductor, so only minimal heat is

transferred from the pot to the cooking surface. In normal operation the

cooking surface stays cool enough to touch without injury after the cooking

vessel is removed. Since the cooking surface is not directly heated, spilled

food can not burn on the surface.

Efficiency

Induction cook top technology gives a far more efficient transfer of energy

than a gas flame or heated electrical element and so boiling a pan of water,

for example, is much quicker. If you are using electricity, induction cooking

is the hands down winner in terms of cost.

The smart way to boil water on our IH GTA 12 Induction Cooker

Limitations

Cookware must be compatible with induction heating; glass and ceramics are

unusable, as are solid copper or solid aluminium cookware. Manufacturers advise

consumers that the glass ceramic top can be damaged by impact. Aluminium foil

can melt onto the top and cause permanent damage or cracking of the top.

The market for induction

stoves is dominated by German manufacturers, such as Bosch, Miele and Siemens.

Taiwanese and Japanese electronics companies are the dominant players in

induction cooking for East Asia

Please note do not be

misled by false sales claims many are simply not true

Induction cookers do save a

lot of energy compared with gas and conventional electric stoves but not as

much as often claimed

Induction cookers do boil

water considerably quicker than gas and conventional stoves

Induction cookers are unable

to cook food 64% faster as is often fraudulently claimed